It’s common knowledge that MRO materials master data is often weak, harming Maintenance Repair & Operations (MRO) business performance. What to do about it in your own business is a different story. One of the challenges is there are lots of records to fix if you want a rational catalogue without several records representing the same thing (all having passed a weak MPN duplicate check).

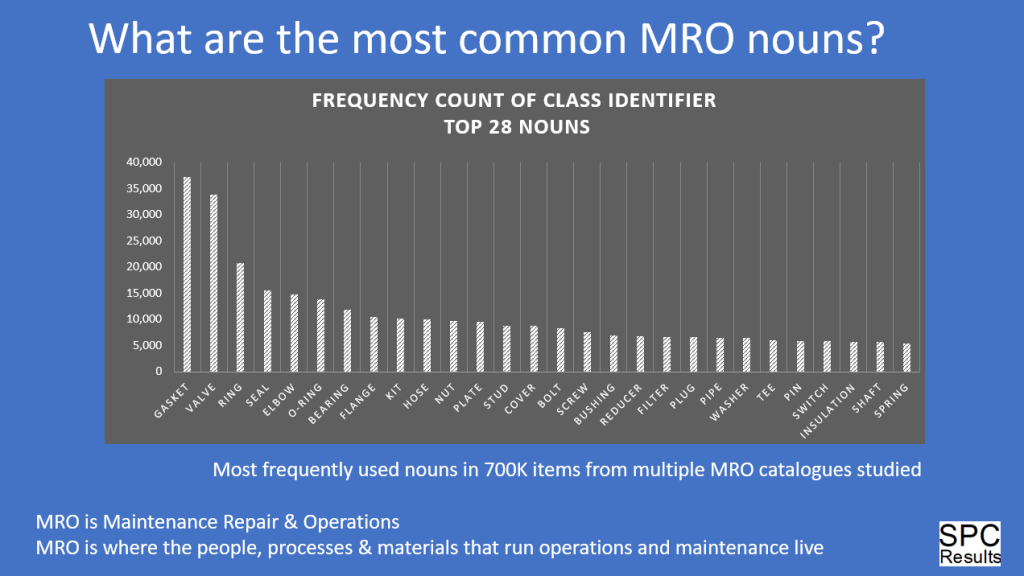

I’ve seen MRO catalogues with 10,000 records, as well ones as having over a million records. Without getting into what to do, how to do it, it must be acknowledged there’s a lot of records to rationalize.

Risk management steers us to prioritize how much effort should be exerted on different categories of MRO materials, so we put the most work where the payoff is best. MRO catalogues have items spanning ready spares for high value production equipment (gas turbines, large pumps and motors) to low value consumables like work gloves and safety glasses.

MRO catalogues have high variability on more than item costs, consideration needs to go to frequency of use, availability of supply, and substitutability. In determining our risk management strategy, we need to consider many levers.

An important lever to discuss is the safety and environmental impact of providing the wrong part. Some items have far greater potential for harm if the wrong material is issued. Fasteners like nuts-and-bolts are not expensive and sound garden variety, but vessels and systems operating at pressure need fasteners with the correct material specs or catastrophic failure can happen. Reputational harm and business interruption are C-suite concerns that come into play after a catastrophe. Am I being over the top here? Material positive identification rules apply on pressure system repairs, so we’re covered right? To me, it’s a poor way to do business to leave disaster prevention to a downstream process, when your job is to supply the right material. If you have quality MRO material master identities, you’ve solved the majority of the getting the right material problem. Quality material identities for pressure systems fasteners need to include key metallurgy specs.

A different realm is avoiding getting trapped by burdensome quality rules to identify low value, undifferentiated items. SPC Results has generic item identity templates for many categories like PPE and chemicals. This simplifies data quality rules management, but still provides consistent structured descriptions.

Applying concepts of risk management guides using appropriate detail for quality identities without overdoing an identity template and creating full product data sheets that stymies the goal of making a useful searchable, rational MRO catalogue.

Let’s discuss your MRO

#MRO