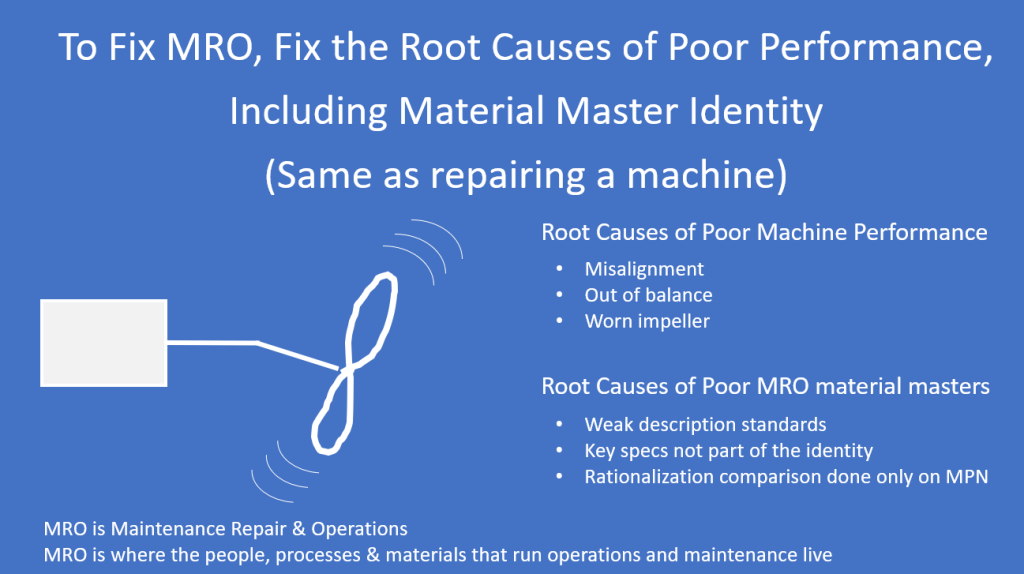

You can compare a poorly functioning overall MRO process to a badly misaligned, out of balance pump with a worn impeller.

To get design performance out of the machine, you need to fix all the causes. Fix one, or some of them and maybe you get better performance for a while, maybe not. You soon go back to a poorly running machine.

If your company runs its business processes on ERP or CMMS and your Maintenance and SCM MRO processes are not performing great, poorly identified MRO material masters are likely a root cause.

I can guide you to make an effective MRO material master identity standard that yields consistently structured item descriptions, includes pertinent key specifications per identity class, then after application of the standard to items, guide item rationalization comparisons beyond simple MPN checks. Having one MRO material master only for each real-world MRO item needed to maintain current assets is possible.

A quality MRO catalogue will likely be significantly slimmer, prevent mistakes and confusion that are the hallmark of poorly running business processes. Make your MRO machine hum instead of shake, rattle and roll. Your team, your colleagues and your bosses will all be happy you did.

Let’s discuss your MRO

#MRO